It's not easy to make a great, long-lasting disc golf bag. If you own a mid-tier to high-end disc golf backpack, can you even remember how many zippers it has or just how many extra compartments are in the pockets behind those zippers? And how many times do you pick it up and put it down during a round? It's at least 50 and likely closer to 100 or more – all while its straps pull against the weight of discs, a water bottle or two, and all the other bits and bobs you carry.

Their complex designs and need for extremely durable materials and construction are what make it hard to create good disc golf bags at low prices. This is true even for bags made with fairly conventional materials and manufactured in nations – often in Asia – where standards of living, worker protection laws, and other factors allow companies to produce textile goods for foreign businesses very cheaply. So, naturally, when someone wants to make a disc golf bag with high-end recycled materials and opts to manufacture in a country with living and working standards like the United States', the price has to go way up, right?

For a long time, there's only been one answer to that question: Absolutely right. But a fairly new company out of Wisconsin, Renu Disc Golf, has just released a disc golf backpack that suggests another one: Not necessarily.

Old Billboards and a Brother-in-Law: Starting Renu Disc Golf

Renu Disc Golf is a collaboration between Andrew Bayliss, Zach Gosse, and Gosse's brother-in-law Benjamin Leibham. Baylis and Gosse are avid disc golfers, and Leibham is a professional industrial designer of soft goods (i.e., things sown out of cloth) who specializes in outdoor gear.

Around three years ago, Bayliss and Gosse got Leibham interested in designing a disc golf backpack as a possible business venture.

"We sat down quite a few times to try to figure out what Zach and Andrew had experienced playing a lot of disc golf, seeing a lot of bags that were out there, and what need in the market wasn't being met – where we could fit in," Leibham recalled. "There's quite a few disc golf bag companies out there, and we tried early to carve out that niche of where we could go."

The lightbulb moment came after the three started thinking less about the specifics of the bag and more about the ethos that would drive their efforts.

"As a designer, there's that double-edged of sword of how cool it is to design stuff and put new products out, but you're also in theory just creating more waste then, too," Leibham said.

Such concerns drive Leibham to approach all of his work with sustainability and minimizing waste in mind, and that lens helped the three partners discover the hole in the disc golf bag market they'd been searching for.

"We saw that there is a gap out there for really sustainable disc golf bags, so that's what we started to jump into," Leibham said.

With this new guiding light, the partners began designing their bag in earnest. After many rounds of sketching, meeting, and resketching, they were ready to make a prototype, which was easier and cheaper for them than most start-ups in the outdoor soft goods space.

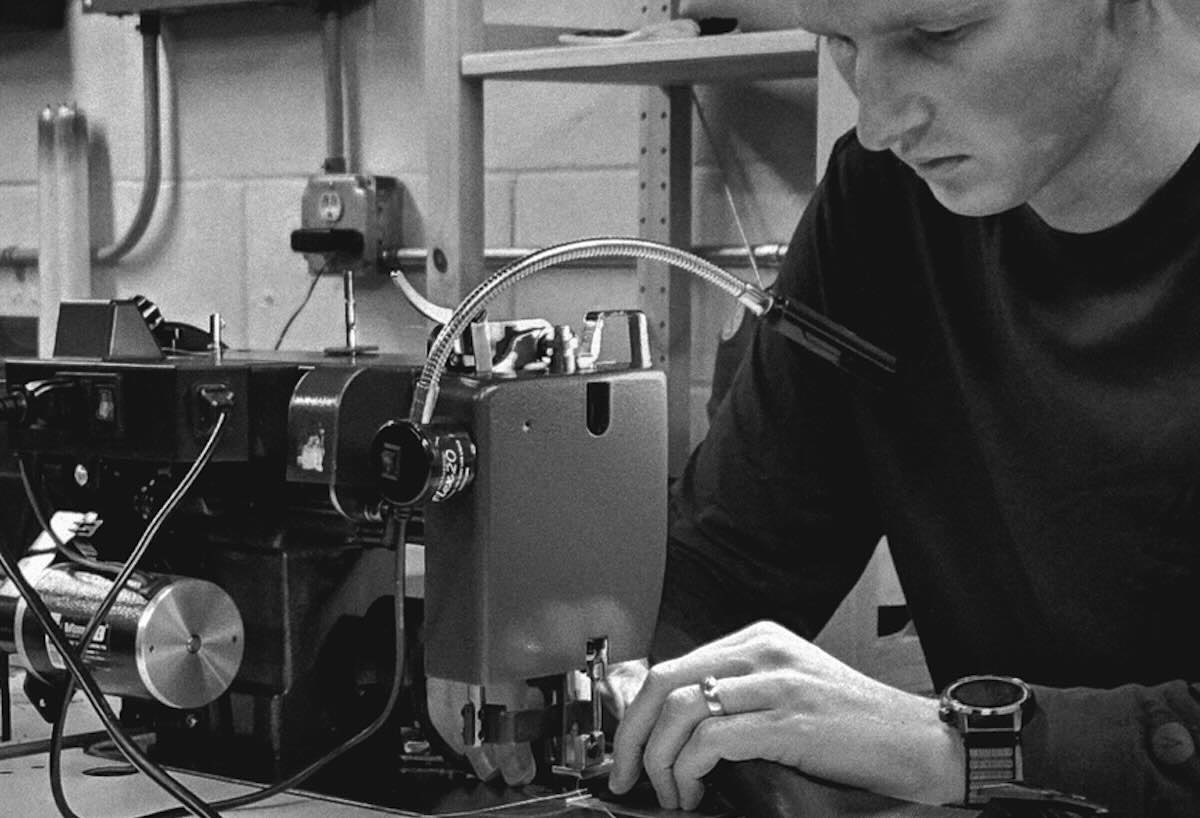

"I've got a lot of sewing experience and industrial sewing equipment, so I started sewing up initial prototypes in my garage," Leibham said.

When Leibham finished a bag, it went out with Bayliss and Gosse for on-course testing. After a few months, the group would talk about what was and wasn't working, and Leibham would create a new version based on their conclusions.

The first prototypes were out of conventional fabrics Leibham could easily get his hands on, but he eventually found a source for used billboard vinyl. He'd incorporated the material into previous projects and also knew of surfing and bicycling equipment companies making successful products with it. The source he found was a local billboard company that was so excited to get rid of old signs that they charged next to nothing for them, giving Renu a chance to upcycle the disregarded billboards into a product plenty of disc golfers would be able to afford.

"The guy we were getting them from had tried to sell them to farms to cover their bales of hay and line ponds with, but it wasn't working," Leibham said. "So he was keeping them all in a barn warehouse outside of town, and he said, 'Well, just give me 20 bucks for the trouble of storing them.' He'd even roll them up really nicely for us so they'd be more manageable because a roadside billboard is like 48 feet [14.6 meters] long."

After over a year of prototype testing and a ton of cleaning and cutting old billboards in Leibham's driveway, the Renu team was ready to hit go on a big run of their first consumer-ready disc golf bag: the EcoPack 1.

To Be Made in the U.S.A., They Had to Go Through China First

The Renu team was proud and excited to share their creation with the wider disc golfing world, but there was one thing they weren't so psyched about. Though they'd tried hard to find a U.S. company to manufacture their first run of bags, they'd been forced to use a Chinese factory instead. According to Leibham, this wasn't due to U.S. companies' higher prices but their lack of capacity and interest.

"We pitched the idea to some sewing shops that I've worked with here in the U.S. and no one wanted to take the project on – essentially because we were an unproven company," Leibham said. "A lot of these little local sewing shops have a couple of clients that they do a lot of work for, and it's kind of a hassle for them to shift around their sewing production for a small business they know might not ever reorder with them."

Though most of the sewing shops gave Renu a hard no on making the company's first run of bags, they didn't completely shut the door.

"A lot of people would tell us, 'Not right now – let's talk in a year after you get them made, and we'll see,'" Leibham said.

Essentially, Renu had to show that its product was worthy of taking up some of the very limited bandwidth of the current U.S. soft good production market. To do that, they had to make it somewhere else first.

A YouTube Bump Leads to Brisk Sales

At about $100 for a 20-disc main compartment, putter pouch up top, and side storage pockets, the EcoPack 1 didn't undercut every bag on the market. Disc golf manufacturing generalists like Innova, Latitude 64, and others offer bags with similar features at equivalent and even lower prices. It did, however, come in at a much lower price than comparable bags from places Renu sees as more direct competition – disc golf bag-focused businesses like Grip EQ, Squatch, Upper Park, and Pound (notably, both Upper Park and Pound utilize recycled materials in their products, too).

The price tag was low enough to help convince players intrigued by Renu's mission to give the EcoPack 1 a try. This was especially true after one of the most influential people in the movement for more sustainable disc golf products, Jesse Stedman of Colorado-based recycled-plastic disc manufacturer Trash Panda, publicly praised Renu's bag and its mission to his tens of thousands of YouTube subscribers.

"I happened to be out near Jesse in Colorado before we were gonna launch, and we shot him an email just asking if we could meet up with him and tell him what we were trying to do," Leibham said. "I sat down with him in his warehouse and talked for awhile, and he was all on board and loved what we were doing. So he made a YouTube video just about our bags."

That video led to over 100 orders for EcoPack 1s in under 24 hours and helped Renu go on to sell 75% of its inventory in just a few months. In less than a year, Renu's entire first run of disc golf backpacks was sold out.

Creating A U.S.-Made, Sustainably-Sourced Disc Golf Bag

Thanks to the success of their first bag, Renu now had proof-of-concept, more capital, and plenty of unbiased customer feedback, all of which they put toward realizing their true goal: Creating a reliable disc golf backpack out of recycled materials manufactured in the United States.

The team had heard from customers and noticed themselves that not all of the billboard vinyl they'd used was as durable as they'd like. Especially in places where the material was constantly folded an unfolded, the vinyl sometimes wore thin or lost its color. For their next bag – the EcoPack 2 – Renu opted for more robust textiles that didn't compromise their commitment to sustainable sourcing.

"We really beefed up the materials," Leibham said. "But we wanted all recycled materials and, as much as we could, U.S.-based materials."

One of the highest-end fabrics in Renu's second backpack is ECOPAK from Challenge Sailcloth, which Challenge claims is "the world’s only durable and waterproof fabric made from 100% recycled polyester fiber and film" and is what Pound – the company many consider the gold standard in modern disc golf bags – uses to make the bottoms of its bags.

"It's puncture-proof and waterproof and all that kind of stuff – you could drop it off a cliff and the fabric wouldn't tear on you," Leibham said.

Along with those upgrades, the putter pocket was tweaked, the main compartment was enlarged, and the straps got more foam padding. But the biggest difference is where the packs were made: A sewing shop in Colorado.

"It wasn't easy finding a place that could take on something as complicated as a backpack and was willing to take a chance on us and spend two months of their production time on such a small company," Leibham said. "The woman we worked with, I've sent her shop work before. So I was able to visit her a few times in person out in Colorado and show her what we were working on. That helped a lot."

Interestingly, it wasn't just the long search for a willing manufacturer that made U.S. production harder for Renu. Leibham said that places like China can generate a usable product with little more than a napkin sketch and vague guidelines for materials, but in the States, sewing shops need precise plans and every piece of material you want them to use.

"If you look at a disc golf bag, there are so many seams all over the place, and that's all a different piece of fabric that has to get cut," Leibham said. "I think our bags have 31 pieces of fabric that get cut uniquley to come together to make a bag. We needed to get the exact shape and dimensions of every single one of those pieces and then we had to source everything."

With the new materials and U.S. manufacturing, the company's cost-per-bag tripled from the first generation to the second. Still, Renu is committed to keeping their prices as low as possible. The new bag's price is around $220, which is comparable to Asian-manufactured Grip EQ's popular AX6 series. It's $50 and $100 less than the least expensive options from, respectively, Gorilla Boy and Pound, the only two other disc golf backpack makers currently manufacturing in the United States.1

"We're trying to keep the bags affordable for people at a price point we're comfortable with and still allows us to reinvest in the business and get it growing a bit," Leibham said.

The Future's in the Bags

If sales and reviews of its second-generation disc golf backpack live up to their expectations, the Renu team's plan is to expand their lineup of disc golf bags made from recycled materials. The most recent release would be their premium bag, and they'd introduce others at lower price points.

One that's already out is their single-strap Weekender. Designed in collaboration with disc golf media company Gatekeeper, it's made of billboard vinyl and doubles as a cooler. They have a few of these still left, and each one was hand-sown in Wisconsin by Leibham.

"The sewing shop in Colorado was busy making our v2 bags, and we couldn't find anyone else to make [the Weekenders] in the timeframe we were looking for, so I basically said, 'Screw it, I'll make them myself,'" Leibham said.

While all three Renu founders still have their normal day jobs, they'd love for their current side business to turn into their full-time work. They believe the path to growth lies in putting out top-notch products and making it easy for potential customers to understand their story, missions, and what differentiates their disc golf bags from more conventional companies'.

"Something we're going to push a lot in our social media is making content about how these bags are made – why we're using the materials we're using and why we're producing in the U.S. and how difficult that really was," Leibham said. "Being open and transparent about that is going to be important for us going forward and helps people buy into what we're trying to do."

1. The original version of this post stated that Pound was the only manufacturer making disc golf backpacks in the USA before Renu's EcoPack 2. Gorilla Boy was added shortly after publication.